- Understand the filament type you’re dealing with.

- Ensure the filament is clean and free from contaminants.

- Crush the used filament to the size of small beads.

- Separate crushed filament by color for consistency.

- Melt the filament at around 190-230 degrees Celsius.

- Re-extrude the melted filament maintaining diameter consistency.

- Spool the recycled filament onto a coil holder.

- Store properly to prevent moisture absorption.

Understanding the Importance of Recycling 3D Printer Filament

3D printing, a revolutionary tech, is becoming increasingly popular especially with the rise in home-based 3D printing enthusiasts. While we’re excited about the potential of these 3D gadgets, we can’t side-step the importance of understanding how to recycle 3D printer filament. In a world that’s becoming increasingly aware of our environmental responsibilities, there’s a pressing need to recycle. Recycling is no longer optional. It’s a necessity. And in the world of 3D printing, we’re not exempt from this environmental responsibility. Everything from the 3D prints to the leftover PLA filament can and should be recycled.

Why should you recycle your 3D printer filament? Firstly, the majority of 3D printer filament is made from PLA (PolyLactic Acid), a thermoplastic material. While PLA is often touted as being bio-degradable, this doesn’t mean it will just disappear if left in a compost heap. In reality, PLA requires very specific, industrial conditions to properly degrade. Without these conditions, PLA can take hundreds of years to break down, just like regular plastic. Thus, rather than binning your unused filament or failed 3D prints, you ought to recycle them.

For those of you who are regular users of a 3D printer, you’re probably well aware that you can pretty swiftly collect a significant amount of wasted PLA. Failed prints, supports, rafts, or even just the unused filament on a reel all add up. There’s no sugar-coating it; that’s a lot of potential waste that we need to take responsibility for. But here’s some good news: you can recycle this PLA filament. In fact, with some entrepreneurial thinking and a smidge of DIY effort, you can create a closed-loop recycling system right in your own home or workspace. Can you imagine recycling your failed 3D prints right back into usable filament? You’d be saving money, reducing waste and doing your part for the environment all at once.

The specifics of how to recycle 3D printer filament can vary based on the type of machine and materials involved. However, the core concept is consistent; reduce, reuse, and recycle. Reducing our consumption where possible, reusing elements that are still practical where feasible, and recycling anything leftover. It’s not just an environmental obligation, it’s a financial opportunity. And in a nascent industry like 3D printing, that is a concept worth reprinting and repeating. So remember, next time you’re at your 3D printing station: reduce, reuse, and recycle, recycle, recycle.

Why Recycle Leftover PLA: Tips on Reducing Waste from 3D Printer Filament

Identifying ways to manage leftover PLA from your 3D printer’s filament is not only economically effective, but it also has environment-friendly benefits – that’s precisely why recycling has moved into the spotlight as a preferred route. When you print, there’s frequently leftover PLA that ends up discarded, contributing to waste. However, it doesn’t have to be so. Various methods are available to recycle this PLA, turning what would have been trash right back into a usable 3D printer component. This effective recycling strategy significantly reduces waste, minimizes costs, and embraces an eco-friendly life cycle for 3D printer filament materials.

Now you’re probably wondering, “Why should I recycle my leftover PLA?” Well, each time you print, the PLA filament that remains is often too limited for another print job, so it winds up in the trash. If not properly managed, this growing pile of “useless” PLA can contribute significantly to environmental waste. By recycling, you transform this “waste” into something beneficial once more – and it’s already attuned to your 3D printer! You’d be realizing an excellent way to manage filament leftovers, generating less waste, and contributing to a more sustainable 3D printing process.

Reducing printer waste makes economic sense too. Recycling spools of leftover PLA can cut costs immensely since buying new filament constantly isn’t cheap. You’ll be surprised at the savings flashing on your financial bottom line when you start recycling your PLA. But how can you recycle these filament leftovers effectively? Multiple handy tips are available to manage your leftover PLA without hitch – many of which have been tried and tested by the 3D printer community.

First, ensure proper storage of your filament leftovers. PLA is sensitive to moisture, so a cool, dry place is best. Second, gauge the amount of PLA left after each print. If there’s enough for a small print job, keep it aside. Third, you can also consider filament recycling machines that melt and reshape surplus PLA into a usable form. These machines do require an additional investment but can pay off in the long run with lower waste and reduced filament expenses. At the end of the day, recycling your PLA is a win-win situation; diminished waste, lower expenses, and a nod to Mother Earth.

Steps to Properly Recycle Your Used 3D Printer Filament

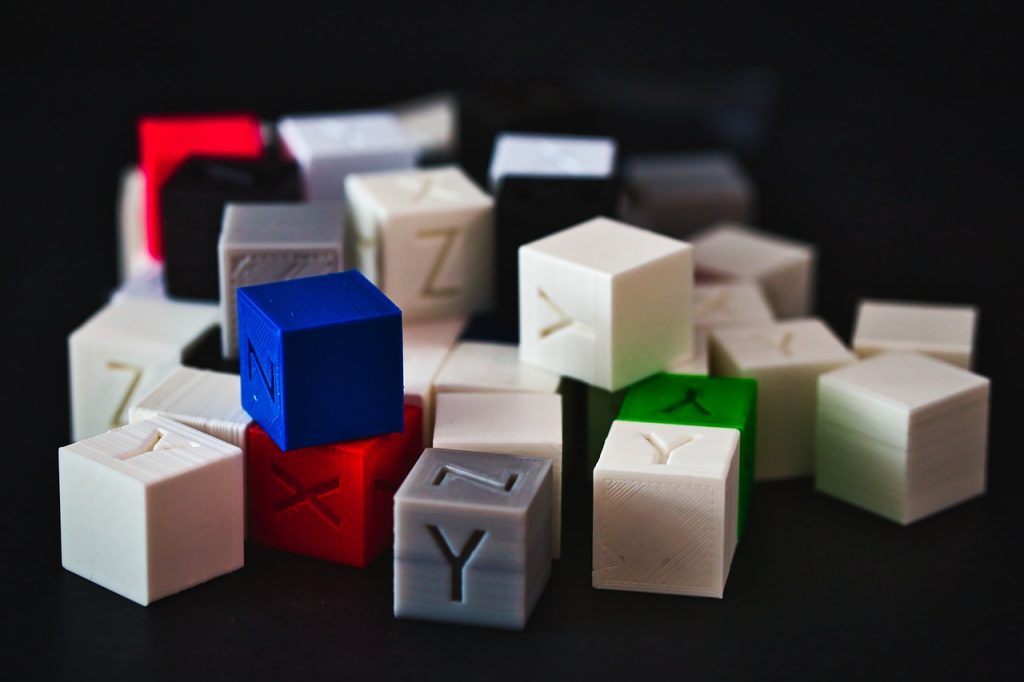

Got stacks of used 3D printer filament laying around? Don’t worry. Here are clear steps to recycle those leftover filaments effectively and reduce your environmental footprint. Firstly, it’s crucial to understand the filament type you’re dealing with. PLA, the most common 3D printer filament, is compostable and can be recycled. Yet, each category of 3D printer filament may require particular recycling methods.

Before recycling, ensure the filament is clean and free from contaminants. Examine the filament closely and remove any elements that aren’t PLA. This step is essential to maintain filament purity and optimise the recycling process.

Now, you’re ready to crush the used filament. Remember, smaller pieces are easier to process, so break your filament down to the size of small beads. Several tools, including cutters and grinders, can be employed for this task.

Separate your crushed filament by color. Although it’s possible to recycle different colored filament together, it’s preferable to sort them to retain color consistency throughout recycling. So, keep your clear, black, white and colored filament separate.

Next step in recycling your 3D filament is to melt it down. Use a household oven or filament extruder to melt the filament at around 190-230 degrees Celsius, depending upon the PLA’s grade. Don’t use too high temperatures, as it can degrade PLA.

Here comes the exciting part of recycling your 3D printer filament. Once melted, re-extrude the filament using an extruder or a machine specifically designed for creating 3D printer filament from recycle material. It’s crucial in this step to maintain the filament’s diameter consistency. It’s also important to cool the extruded filament slowly to prevent warping or other deformations.

Last but not least, spool the freshly recycled filament onto a coil holder. Now your filament is ready to be reused for your next 3D printer project. Just remember to store it properly to prevent absorption of moisture, which can adversely affect the filament.

So, why not set aside your 3D printer for a moment and start recycling those used filament? By following these steps, you’ll not only be able to recycle your used filament but also help cut down on the global waste problem. So start recycling, because every little bit counts.

How to Reuse and Repurpose Leftover PLA from Your 3D Printer Filament

Reusing and repurposing leftover PLA from your 3D printer filament shouldn’t be an intimidating task and it shouldn’t be overlooked in your 3D printing process. Instead of discarding your unused filament, there are several ways to creatively repurpose PLA filament, offering you more value for your money while also reducing waste. Consider the potential benefits of transforming leftover PLA filament into other printing resources, or even into non-printing related items.

One of the primary ways to reuse PLA filament is by converting it back into a printable form. This task requires a specialized filament extruder, a device typically used for changing plastic granules into filament. Here, you’ll chop the leftover PLA into smaller pieces and input into the extruder, which will then churn out regenerated PLA ready for printing. This innovative way to reuse your printer filament not only maximizes the value of your initial purchase but also contributes to a more sustainable 3D printing practice.

Equally, you can repurpose leftover PLA from your 3D printer filament into different artistic or practical objects. With a bit of ingenuity, you can transform PLA scraps into unique jewelry pieces, decorations, or even small household items. These reimagined creations provide an exciting and resourceful means to use up leftover PLA material, showcasing that 3D printing isn’t limited to the initial intended design.

Furthermore, recycling doesn’t have to be a solo effort. Take note of companies such as Filamentive, which are actively promoting responsible 3D printing usage by engaging in sustainable production and recycling initiatives to repurpose PLA and other filament materials. By aligning with such brands, users can achieve more sustainable practices with their 3D printing. With collective efforts, the 3D printing world can move towards a circular economy model, where leftover PLA is continually recycled and reused, creating less wastage and promoting more sustainable practices.

Consequently, the importance of learning to properly recycle and repurpose PLA from your 3D printer filament can’t be overstressed. We’ve got one world, and every 3D printer user should strive to minimize waste and maximize usage in their practice. By considering these tips, you can be part of the solution rather than adding to the problem and start making the most out of your 3D printer filament today.

PLA: The Eco-friendly Choice for Your 3D Printer Filament

Throughout the process of 3D printing, there’s no doubt that you’re bound to have leftover PLA. The question remains: what should you do with these extra remnants? The eco-friendly choice lies in taking another look at the PLA and considering it as more than just your regular 3D printer filament. It’s a material that you can recycle, preserving the environment and cutting down on waste.

This is particularly significant when you realize that PLA, or polylactic acid, is an incredibly common 3D printer filament. Made from renewable resources like corn or sugarcane, PLA stands out as an eco-friendly choice both during its production and its afterlife, once it’s no longer needed by your 3D printer. With more and more people using their 3D printers at home or work, it’s essential to know how to minimize waste and recycle 3D printer filament effectively.

Your 3D printer is a fantastic tool, but it’s not as environmentally friendly as it could be without recycling options. There’s where PLA comes in. With proper recycling, any unused filament from your print jobs can be transformed back into usable filament once more.

Choosing PLA, when you print anything on your 3D printer, is a beneficial eco-friendly choice that helps reduce waste and protect the environment. When you recycle 3D printer filament, you provide a second life to the leftover PLA and prevent it from ending up in our landfills.

Steps to recycle PLA can be straightforward. The process involves a machine known as a filament recycler, which grinds and reshapes the leftover PLA into new 3D printer filament. The result is an impressive, eco-friendly option for your 3D printer, which also encourages the reusability of PLA.

PLA, therefore, is not just another 3D printer filament. It’s an eco-friendly choice worth making for every 3D printer user. By recycling the leftover PLA from your print jobs, you are not just keeping it out of landfills but also contributing to a sustainable future where 3D printing can continue to thrive without being burdened by excessive waste. So, the next time you print with your 3D printer, remember: you’re not just printing — you’re making an eco-friendly choice.

Companies Leading the Charge in The Recycling Filament Movement

There are several companies leading the charge in the recycling filament movement. Making serious strides in the industry, they’re bringing about significant changes to the way we recycle 3D printer filament. To say they’re leading the charge is an understatement; these innovators are paving the way to a more eco-friendly future in 3D printing.

First off, it’s important to appreciate the filament recycling process. It’s not simply a matter of taking old filament and reusing it. The recycling process includes cleaning, melting down and re-extruding the filament to ensure it’s in perfect condition for its next project. Companies specialising in this are making great advances, reducing waste from 3D printer filament and making the sector more sustainable.

These recycling companies, dedicated to the recycling filament movement, are fostering more efficient and sustainable practices. If you’re left with leftover PLA from your 3D printer filament, they’ve got a solution. Instead of wasting your filament, they’re offering avenues for recycling – and that’s great for the environment.

Speaking of PLA, it’s an eco-friendly choice for your 3D printer filament due to its biodegradable properties. PLA stands out in the filament market due to its green credentials, making it an obvious fit for the recycling filament movement. Through recycling PLA, these companies are creating a more sustainable option for 3D printing enthusiasts.

But, how do you go about recycling your used 3D printer filament? We’ve previously touched upon steps to properly recycle your printer filament. Remember, you should clean and dry your leftover filament before sending it off to a reputable recycling company. It’s these companies that are making strides to recycle filament responsibly and innovatively.

Brands like Filamentive are at the forefront of the recycling filament movement through their high-quality recycled filament. They’re not just creating green filament, but they’re also promoting responsibly sourced materials – showing that you can have quality and eco-friendliness in one package.

To sum up, these companies are leading the charge in the recycling filament movement, making 3D printing more sustainable. From recycling PLA to developing new filament recycling methods, they’re setting the standard for others to follow. So, let’s appreciate these pioneers in the recycling filament movement and support them where we can.